Yep, that’s the “fulfill minimum” setting on the item coverage/general tab. Set it to “first issue” to do what you’re asking for.

Hi Chan,

If I set it as “First issue” the replenishment is set on the first requirement (if total requirements are higher than on hand inventory without including safety stock) not when the stock is going to fall below the minimum point. The next example illustrates it:

1/1 On hand: 100 (Safety stock: 50)

10/1 Replenishment order: 50

10/1 Requirement: 30

16/1 Requirement: 60

I want it to replenish the safety stock on 16/1 because there’s when the stock will fall below 50.

Is that possible?

Thank you.

Regards,

Nacho

What you’re describing sure sounds like a bug, but I’d be surprised if that’s really the case. All of your examples going back to the start of the thread essentially illustrate that the onhand inventory is not being considered a source of supply. Suggestions have focused on the potential reasons that inventory could be excluded from the planning process, and you’ve ruled all of them out. Therefore it’s either a bug, or our collective wisdom is missing a possible cause.

Just for kicks, create a “real” (not planned) MO or PO for a quantity that matches your onhand, make it due [today], and zero out the inventory for the item. Then rerun MP and see if you get the same result. That could at least clarify whether time fences and positive/negative days are a factor. If it looks fine (does not generate planned order until cumulative net requirements project inventory to below minimum), then you know the issue is definitely bug or something “wrong” with the onhand inventory that is making it non-nettable.

In your example you ask if it is possible to create the replenishment order on the 16th - the answer is yes, that is how it works!

First issue – The specified minimum quantity is met on the date of the first issue that is scheduled during the time period that is specified in the Coverage time fence field.

I have never set it to First issue because I see little point, I am more interested in the trigger point, your trigger point is the 16th but there is an earlier issue in the time period. If you set it to todays date as an example it would be the 16th (other impact being ignored and assuming a simple setup!!)

Hi Adam,

If I’ve understood you right if I set Fulfill minimum as “Today” the replenishment order will be placed on 16th because there is when the actual requirement exists. But if I do this the safety stock requirement and therefore the planned order is placed today. Below is placed the picture for better understanding.

As I said, my wish is to have the replenishment order on 3/13 because that day the stock will fall below the safety stock, but AX is placing the safety stock requirement today.

Is that a bug? Or I am missing some system customization?

Chan I hope I have answered you as well.

Thank you both.

Regards.

I think the settings for fulfill minimum are just noise covering up whatever the real issue is. What I’d suggested was that the inventory is simply being ignored entirely by the MP/netting process, and all the hoops you’re jumping through switching that setting, or changing the coverage to period, or worrying about whether the individual demand records are greater or less than the current inventory are not immediately relevant. What’s immediately relevant is figuring out why the current inventory is not being netted.

Looking over the thread, we can eliminate insufficient positive days. We can probably rule out batch attributes like expiration date. We can probably rule out things related to other planning dimensions such as the inventory is in a non-nettable location, or doesn’t match the demand on some other dimension like size/color/style.

What I’d suggested as a test was to put it back on min/max, place a PO or MO matching the inventory quantity with a due date of [today], zero out the inventory and rerun MRP to see if you get the same results. If you do, then this proves either a bug or something wrong with the configuration or parameters. If you don’t, and instead find “good” results with no unnecessary planned orders, then this would confirm the problem is the inventory or a bug.

I doubt it’s a bug, because I’ve successfully seen min/max planning work fine, including in environments with forecasts.

One other note–you’ve described several times now the min/max minimum value as safety stock. Safety stock is not the same thing as minimum inventory level, even though min/max planning repurposes that field. Safety stock would be considered a separate demand record, so if you really have safety stock and have set that up via a safety stock journal rather than a coverage minimum, then this could explain what’s going on because inventory would be getting pegged to the safety stock requirement and therefore be unavailable towards the minimum (and to me, if a safety stock were included on a min/max item, this is a design flaw that probably wouldn’t be classified as a bug).

Would BOM/route version requirements in the coverage groups cause this?

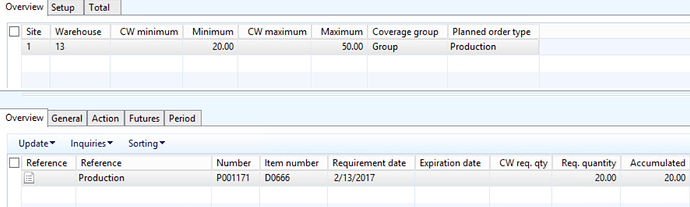

Just to reassure you it works I created a new item, set the coverage group as per yours, added a forecast, manually booked in stock and ran planning. As you can see it works.

You mentioned customizations, if you have any remove them. After that start checking you plan settings, but there is so much in there it is difficult to point out, Chan’s suggestion is a good one to strip it back. Create a new item and do what I did, is it the same result. Mine has no BOM and I dont think it impacts Jake, but remove the BOM!

AX works in this area with a simple config, it is finding what is wrong with yours that is the issue.

Hi Chan,

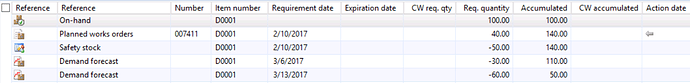

I have done the test you proposed (if I understood it right) and here are the results. The MRP still working the same way:

The safety stock is being defined as the minimum key, I’m not using the safety stock journal.

If it is not a bug then I don’t know where the configuration mistake could be.

Any help?

Thank you all.

Regards,

Nacho

Okay but you have actions and future messages there which will not be helping - what are they saying and how have you configured that.

You have not setup a new item have you? Why are you getting other elements impacting if it is clean with 2 forecast records, stock and then run planning?

Hello,

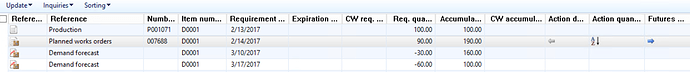

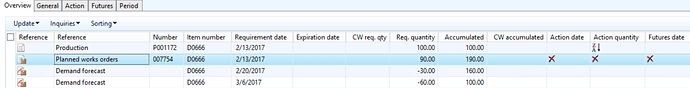

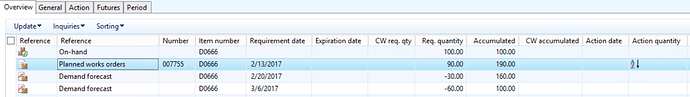

Here is the test with a new item. It works exactly the same way as before:

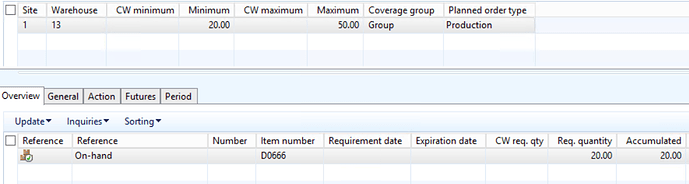

But as before, the results are the same if I just have 20 units on hand:

The problem appears when there is some forecast and stock falls below minimum stock:

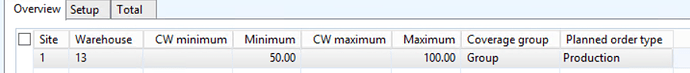

This is the configuration for the test and the coverage code is Min/Max:

- With production order:

Action messages are telling me to cancel the planned order and increase the quantity of the production order.

- With on hand inventory:

Action messages are telling me to decrease the quantity of the planned order.

I want the order to be placed the 3/6 because that day the stock will fall below the minimum stock.

I hope this was the test that you wanted to see.

Thank you.

Regards,

Nacho

Make it simple. Only have a forecast, build it in layers, you have seen my example works. Check it works without existing supply, then work on demand consumption of forecast along with action and future settings.

OK, based on your post #485790 from about an hour ago, assuming the first two screen shots show net requirements AFTER running MP, then you’ve verified that when inventory or scheduled receipts are greater than the minimum, no planned orders are generated. That’s good/as-designed.

Your next screen shots show that when demand enters the picture and projected inventory falls below the minimum, MP generates planned orders for appropriate quantity (results in min/max “max” level at end of the horizon), but the timing appears to be to the first requirement even though that requirement is not the point at which you fall below minimum. There are multiple options you’ve got for timing, but none of them fit “when projected inventory falls below minimum”. That’s not how min/max coverage policy is designed to work. The whole point behind using “max” in min/max is because you wouldn’t normally know what demand will be–that’s why you have to tell it how to calculate how much is needed via entering a max value. If you know what the demand is expected to be, which is what you’re reflecting by using a forecast, then your coverage method should be period or requirement, not min/max. You’re using the wrong tool for this particular job

You can still use safety stock under those methods, just can’t use a max inventory. The max inventory would effectively come down to coverage details like order min/max/multiples, period of coverage, etc.

I think what was confusing me (and probably others) is that you kept describing the problem as a case where orders were being generated inconsistently, under some scenarios but not others. That doesn’t seem to be the case. I don’t see any screen shots where your planned order quantities look wrong, or where there’s a planned order that shouldn’t exist–I just see dates different than what you want.

Hi Chan,

Sorry if I didn’t explain myself right and I confused you.

You have detailed pretty accurately my problem.

The real problem is that the safety stock is being replenished on dates that don’t make any sense for me.

My goal is to achieve the MP to work as in Adam’s picture, but I’ve been trying this for days with different configurations and as much as I read “Today’s day” key is to replenish the minimum on the day that MP is executed. So I can’t find how to make the MP works the same as Adam’s (replenishing the minimum stock the day that stock falls below minimum quantity).

Thank you both.

Regards,

Nacho

Take out the production order that was not created by planning because it is confusing you. Start with minimum stock level set, stock above it and future demand. When you bring in other supply it changes the picture. Start simple.

Yes, but note that in Adam’s example, he was using PERIOD as the coverage method, not min/max, and he used a safety stock of 50 with no “max” value since period does not allow this. The fulfillment minimum setting under period coverage is irrelevant/does not apply.

So the solution to your original query is to change to period coverage, not min/max, since min/max is not the best fit for multiple reasons–#1 because you are reflecting anticipated demand, and #2 because you want the timing of the replenishment to be based upon this demand, not just because an onhand circuit breaker has popped.

I used period because I copied the screen shot in the post before when the net requirements were wrong, min/max would not matter in that scenario.

I’ve done it and I understand everything that happens step by step as I make the test more complex, but whenever the stock is going to fall below the minimum stock, the key “Today’s date” creates the order for the minimum replenishment today and the minimum stock requirement is placed today too.

I can’t explain what happens any better, sorry :S

Thank you both.

Regards,

Nacho

So what is the production order doing in your last example?

I copied your settings to show it working, create a new item as described and if it is still not working screen shot your settings like last time and I will update mine to reflect then we can pick differences apart. If you start midway it is harder.