Hello All,

I have had this nagging situation for a while now, that our production orders resource capacity scheduling (WrkCtrCapRes) gets deleted when the order is started.

I cannot seem to figure out how I can keep the resource’s capacity till the production order goes to ReportedAsFinished.

I’m 95% sure there is a setup option to change this behaviour, though I cannot locate anything useful that works.

Can someone assist in helping me change my systems default behaviour to retain the capacity scheduling slot till the production order is reportedasfinished (endjob = true).

Thanks in advance.

Thanks Tj

Do you forward flush the routing at start?

Hello Adam,

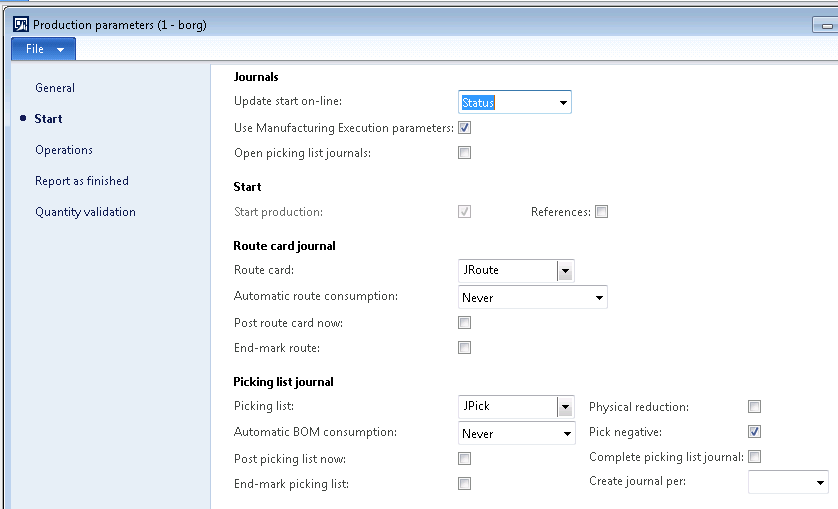

Thanks for the prompt reply. Currently we have the route and picklist set to “Never”, as we prefer. Hopefully the images are visible to you below. Fingers crossed.

Below is a single production order Start setting sample.

Production parameters below (we do not have site override ones)

Manufacturing execution → production parameters → Start

Manufacturing execution → production parameters → Operations

Okay so you are using MES? Are you recording time through MES?

If you look at a newly started production order what do the open jobs look like/route card look like/production posting look like/route look like?

Forgot to mention that we are also using R3 WMS and our items are WMS enabled. Shouldn’t make a difference though.

We do not utilise any of the feedback / time / MES functions as such, we have automated WES systems which understand output quantities, and basically use the following steps:

Not sure if the below would be classed as the AX MES you are talking about, though we basically just:

Release → RAF (endjob off) → RAF (end job on)

-

“Release” production order in AX, which basically just inserts it into our external WES automation system

-

Product processes through our WES system

-

AX periodically looks at the WES to see what’s complete

-

We then RAF (endjob = false), as still more to come.

- This inherently goes through the prodmultiincreasestatus to Started, hence dropping the machine resource.

- We then RAF (endjob = true), once completed in WES.

Hopefully I’ve added enough information.

If you look at a newly started production order what do the open jobs look like/route card look like/production posting look like/route look like?

I would suggest your WES interface is causing the issue. If you release an order you then start it, the capacity remains taken until the job is reported. If you take WES out then the capacity remains until you report it.

Hello, Thanks again for your time as below you’ve help answer my question.

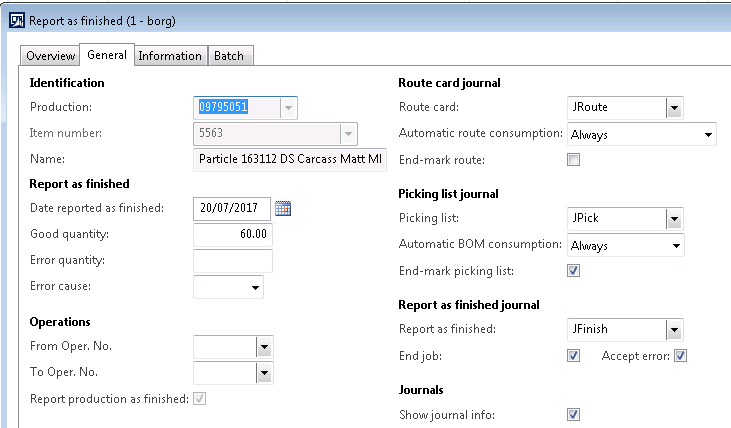

You’ve helped me get to the solution, as it seems all this time I’ve just misunderstood the meaning of “End-mark Route”! I always thought you needed this set to post them automatically :-(. See my detailed example below, it was a RAF setting not Started, as you suggested.

I probably could have left the WES portion out also, to not confuse things more, as it still removed capacity irrelevant to the WES interactions. Sorry about that.

See below the answers on a sample in our DEV system.

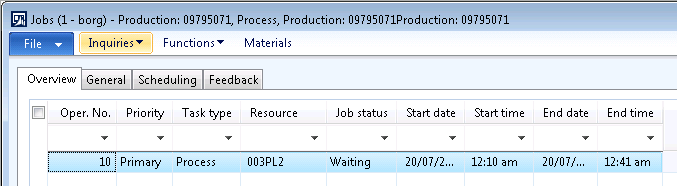

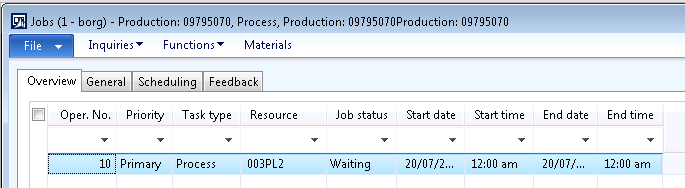

At “Scheduled” status

Jobs:

At “Released” status

Jobs:

Starting options:

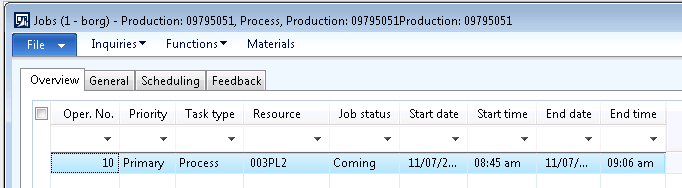

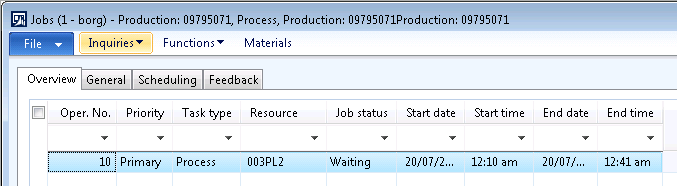

At “Started” status, kept the resource

Jobs:

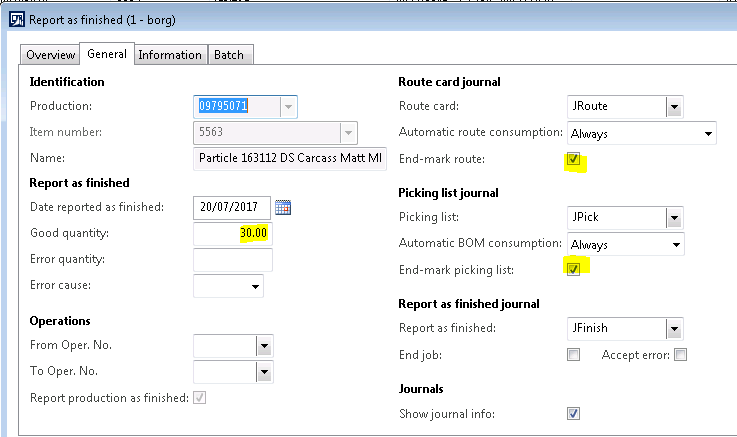

RAF first lot of Qty 30 options:

RAF info

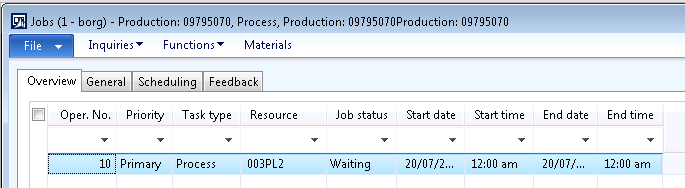

At “Started” status still, kept the resource for remaining 90 to make. Beautiful!

jobs:

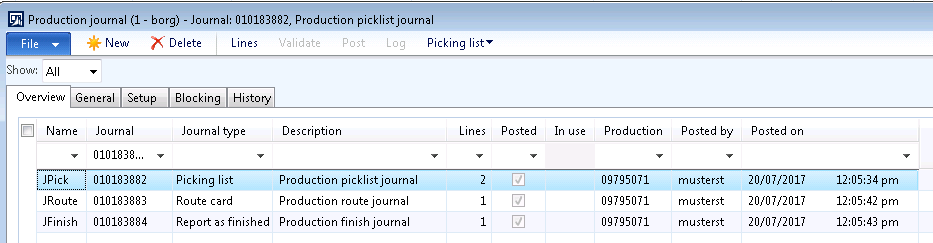

Journals:

RAF second lot of Qty 30 options: Setting End-mark’s, as our automation does.

RAF info:

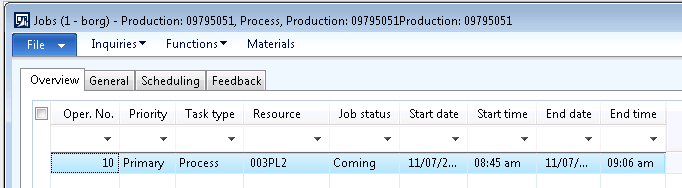

At “Started” status still, resource gone for remaining 30 to make. Found my settings difference!

Journal:

Sorry and Thanks for your time, greatly appreciated