If a manufactured item(FG) has only on raw material(RM) & only one operation.

The time required for manufacturing one unit of FG is 5days & purchase leadtime

for RM is 2 days.

What should be the manufacturing lead time for FG is RM is not in stock = 5 days or 7 days.

I made a Sales Order of todays date & got a planned batch order after 7 days means AX is taking 7 Days.

Manufacturing lead time should only be the time required to process unit quantoty(Setup+run+que+move+)

of he FG & shoul not contain the RM prurchase lead time right?

The manufacturing lead time should only be 5 days. The RM should have a purchasing lead time of 2 days. Then the master planning based on the sales order of the FG will tell you when to start the production order, and based on that date and the BOM, it will tell you when to submit the purchase order to the supplier. There are other parameters that could be used as the positive and negative days for example.

It works it out perfectly, you have no RM, you need 2 days to buy it, you can then start production which takes 5 days, so from the perspective of the sales order you can have it in 7 days - you cannot start production today when you have no RM. If you have RM then the sales order would be 5 days, the time to manufacture it ONCE you have the stock.

Hi Adam,thanks for the explaination.

Shouldn’t it work with SO date future.

Example:

I have a made a SO of 64 quantity which will require 4 days to manufacture.RM has 5 days lead time to purchase.

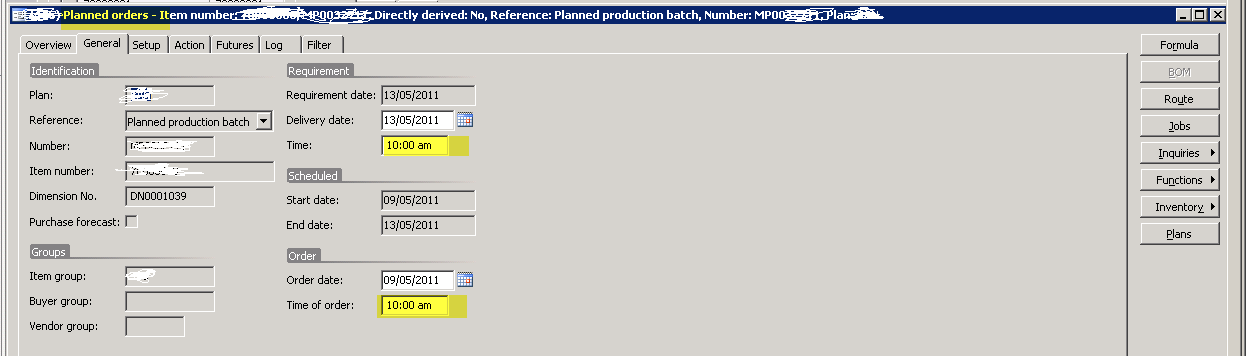

The SO delivery date is 13th May 2011 hence as per your last reply lead time here also should be 4+5=9 (because RM not in stock) hence AX should give a batch order with start date=3rd may 2011 & end date 13th may 2011…but AX is given start day of **9th may 2011 ,**end date is correct which is 13th may 2011.

What can be the reason.

4 days to Manufacture. So need on 13th, less 4 days is 9th, so start of the batch is the 9th.

The purchase lead time will work back from the 9th to the 4th. Have a look at the explosion from the sales line and you will see the related purchase order.

Adam,to add more to my last update…

9th may to 13th may means it takes 5 days.

Working times are 7 am to 3 am but as shown bellow the time in planned order is 10 am hence one extra day added to 4days hence 5 days…still its not 9 day …means not included the puchase lead time…whyt???

-

The palnned start and end times have been defined by you in the planning parameters. The receipt time would be on the PO impacting on the start time of the production order.

-

The purchase lead time is irrelevant to the lead time of the works order, it just dictates when it can be started.

Look at the job scheduling and then compare it to the receipt time of the planning parameter.

additional question…from where this 10 am is taken as shown in yellow.

Hi,

The time 10 am is been taken from the Master Planning Parametes–>Planned Order screen - Reciept time.

This is the default receipt time for proposal for the planned orders.

Regards,

Satish EC

I had already found it but thanks for the update.

Now only question remains is why purchase time of the Raw material is considered in calculating the start date of planned batch order…any idea??

I mean:

why purchase time of the Raw material is NOT considered in calculating the start date of planned batch order…any idea??

You have told the system you expect the goods to be received from teh supplier on this date by 10am. What would be the point in starting production at 6am when you do not have the product?